Thanks for the "how-to" for pics. I'll give it a go.

Here's the latest. It's been a roller-coaster to say the least. As you may recall the gib key on the left (fuel pump side) flywheel (FW) has been removed. Last I wrote I was applying pressure to the right gib-key. Before going to work I gave the jacking screws about 20 degrees rotation and I heard a PATING, clatter as the head of the gib key seperated and hit the barn siding and skittered around the floor. Good-news: the key puller is undamaged. So I went back to work on the left FW.

A buddy of mine had a bearing seperator and a couple of gear pullers so I bought some 5/18-18 threaded rod and hooked the two together as shown

. After letting it stand tensioned overnight with KROIL, I disassembled and applied anti sieze compound on the threads and on the thrust washers. After snugging everything up I rotated 7 flats. Then I did what my friend suggested, I give the center jacking screw a firm hit with my 2lb sledge. When I did it the FW rang and then immediately stopped. I noticed the hub moved the tiniest amount. Rotated another flat on both of the outside jacking nuts and a whack to the center jacking screw and it moved again this time more. I continued to do this until the hub was 1/4 closer to the end of the shaft and I realized I was bending the bearing seperator bolts. I removed the bearing seperator and will be jacknig the FW off tomorrow. Daughter's birthday today.

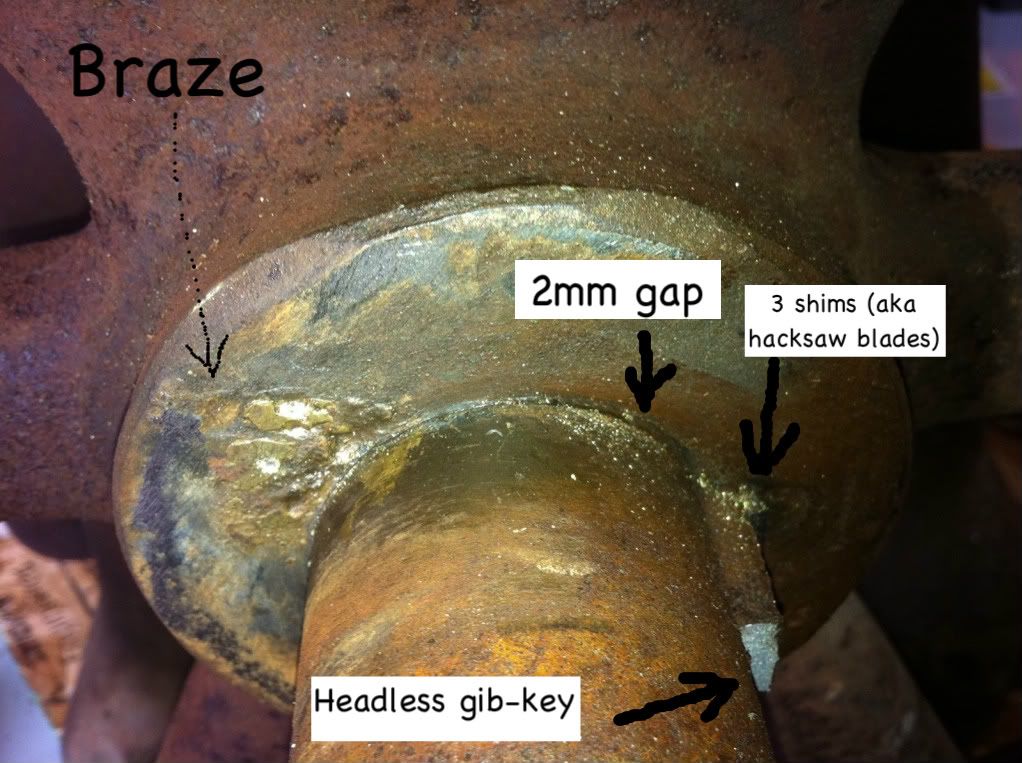

I feel lucky its moving, the rght side looks like it is firmly brazed to the shaft

. I didn't notice until today that there is a 2mm gap between the shaft and FW hub on the right side. I have to get the key out first. I'm planning on welding a threaded rod to the key and using it to make a slide hammer.