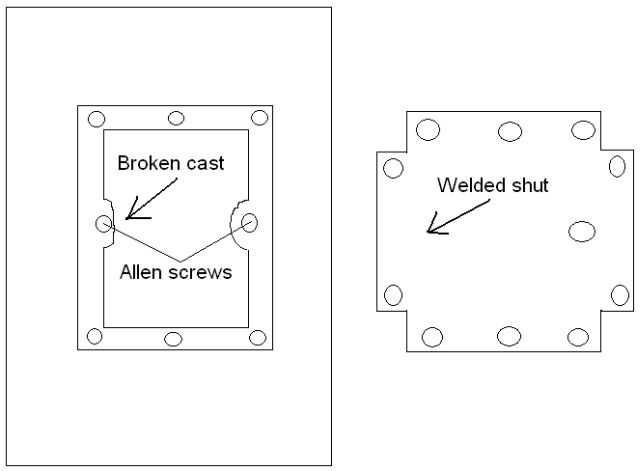

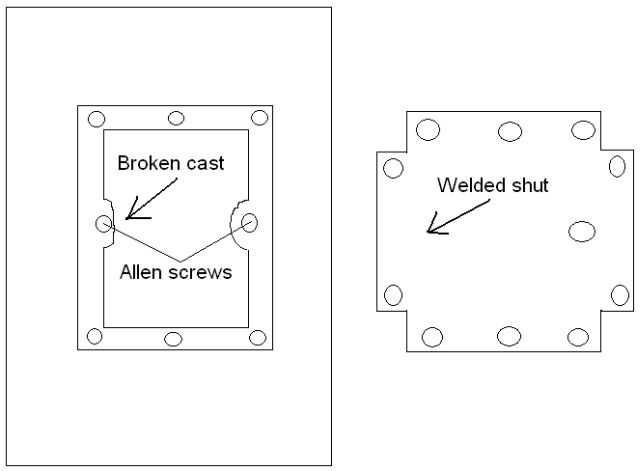

On a different topic. Water leaks. Water was leaking out of the block side cover under the fuel filter. I found a place where the casting was broken away beside a bolt hole where an allen screw stud or hole filler was placed. So I welded some metal onto the bad spot and ground it off smooth. After putting it back together, taking it apart, repeat,pull out some more hair, water still leaked out around the allen screw. It seem there is a pin hole leaking into the bolt hole where the allen screw is. I was using a "minuet gasket" product that maybe should had set up longer, but it would not seal the leak. I ended up just welding the hole shut on the cover. If The hole is ever needed I can drill it out agsin

Also had a leak around a stud on the bottom water port flange. That got "blue goo" and seems to be holding.