1

Engines / Re: Lister SR2M project.

« on: July 15, 2020, 03:35:59 PM »

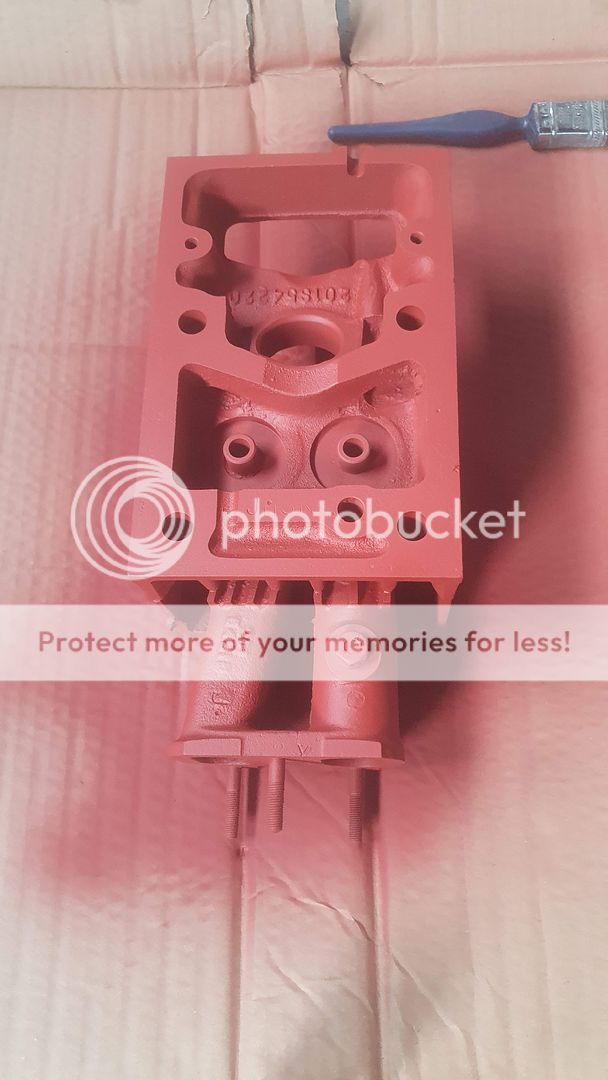

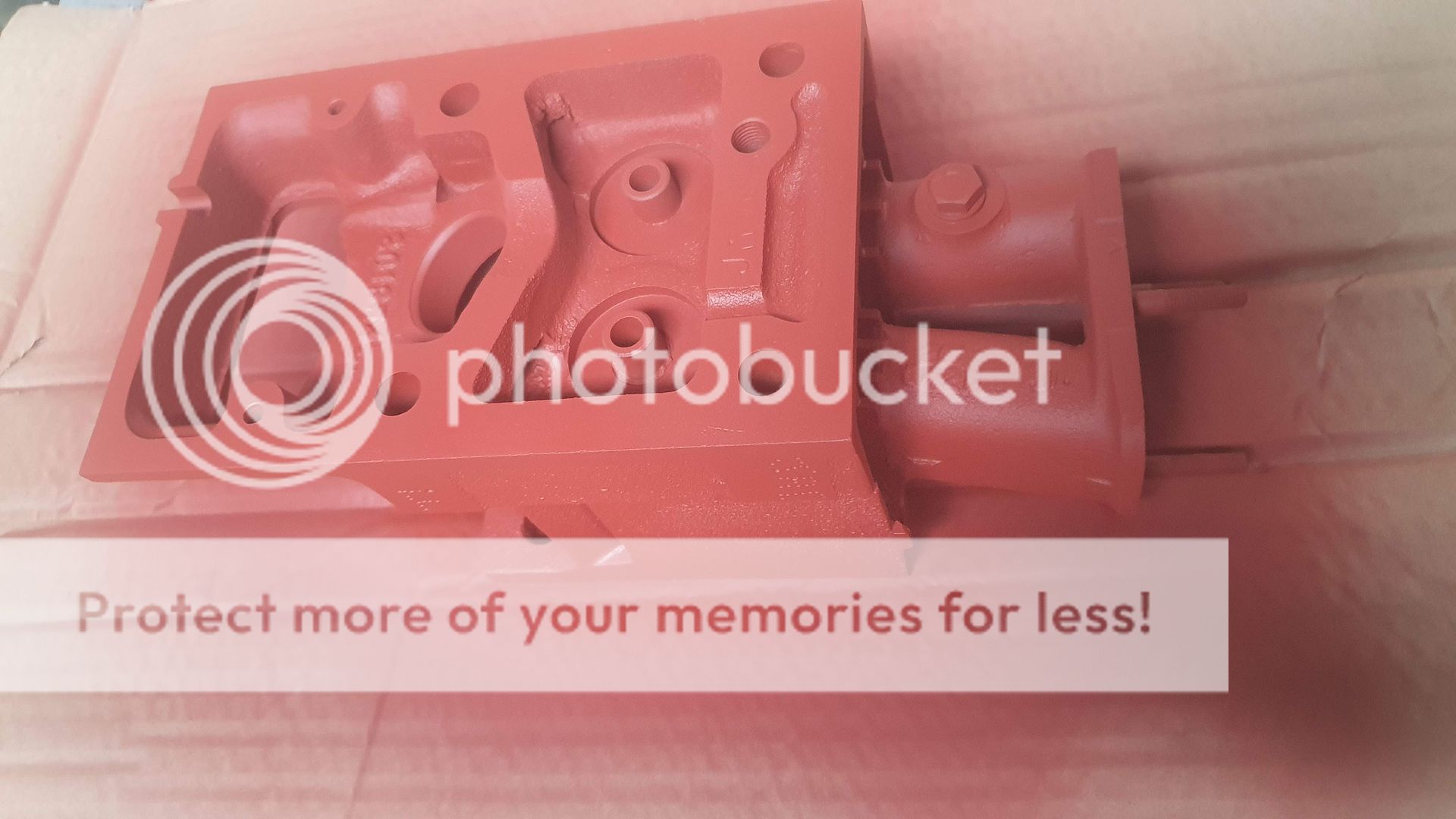

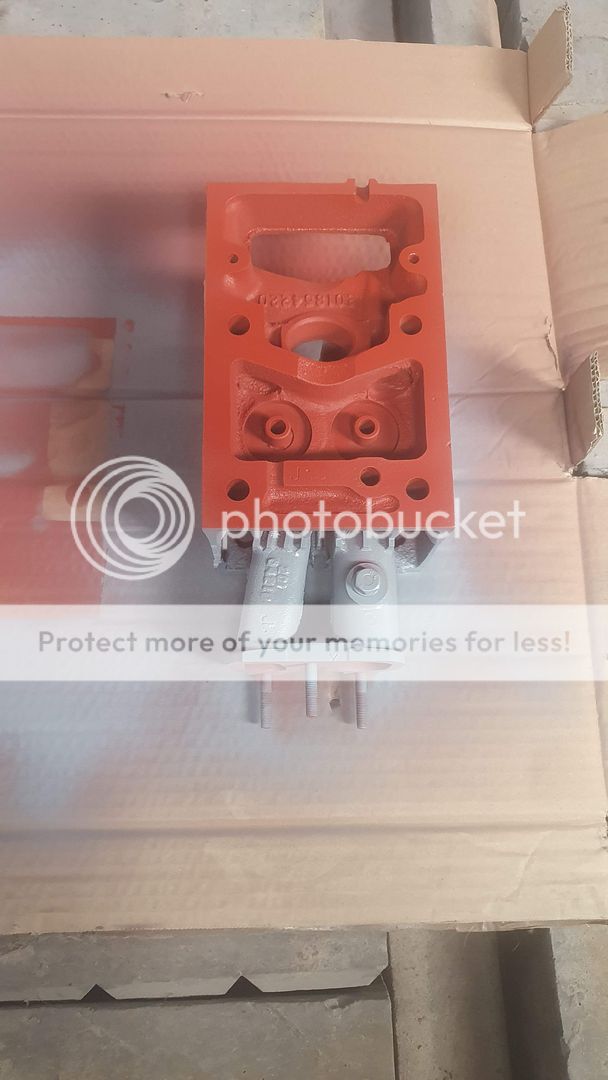

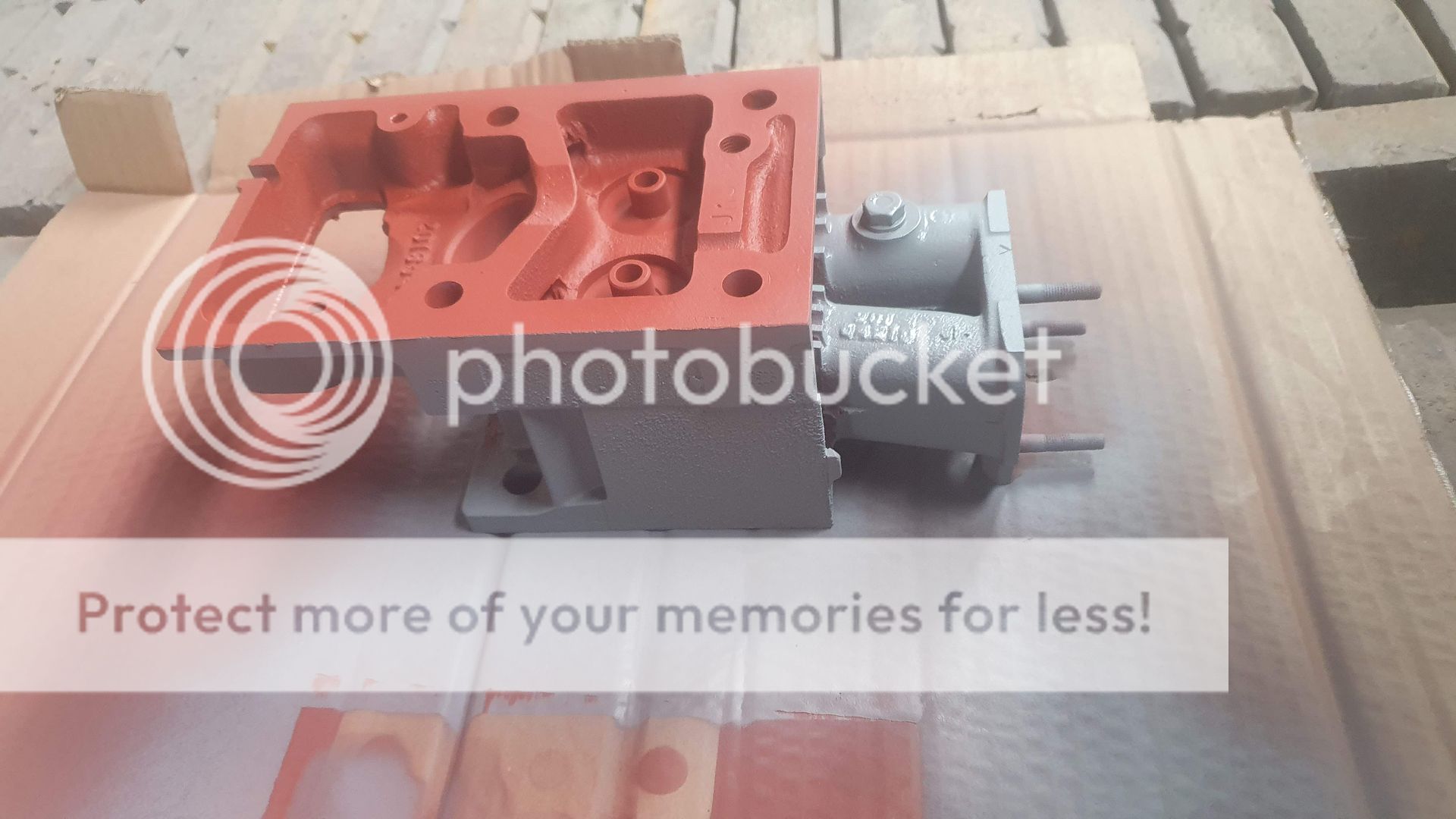

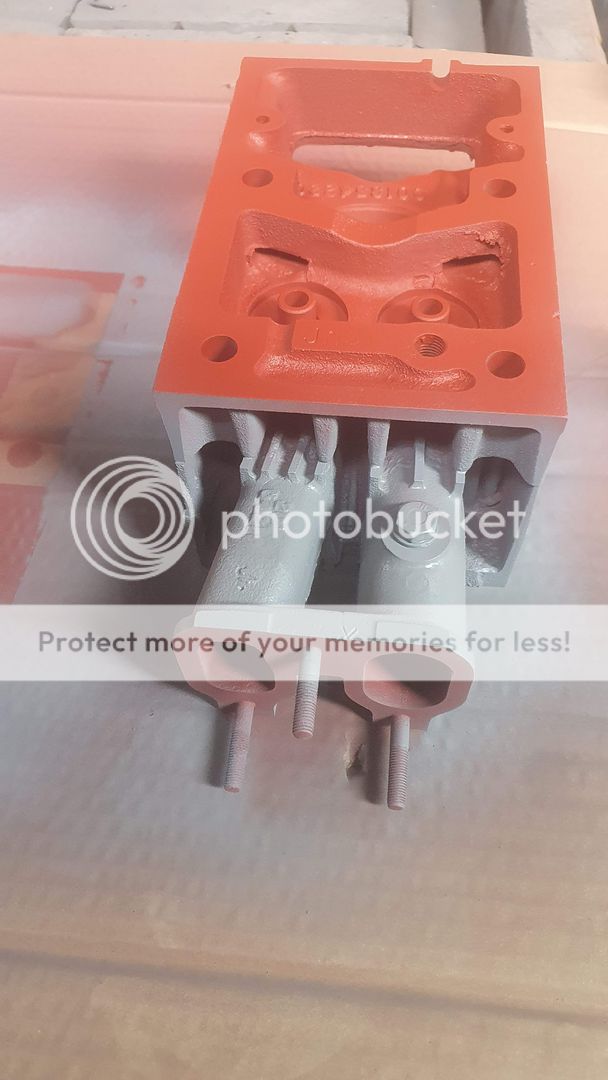

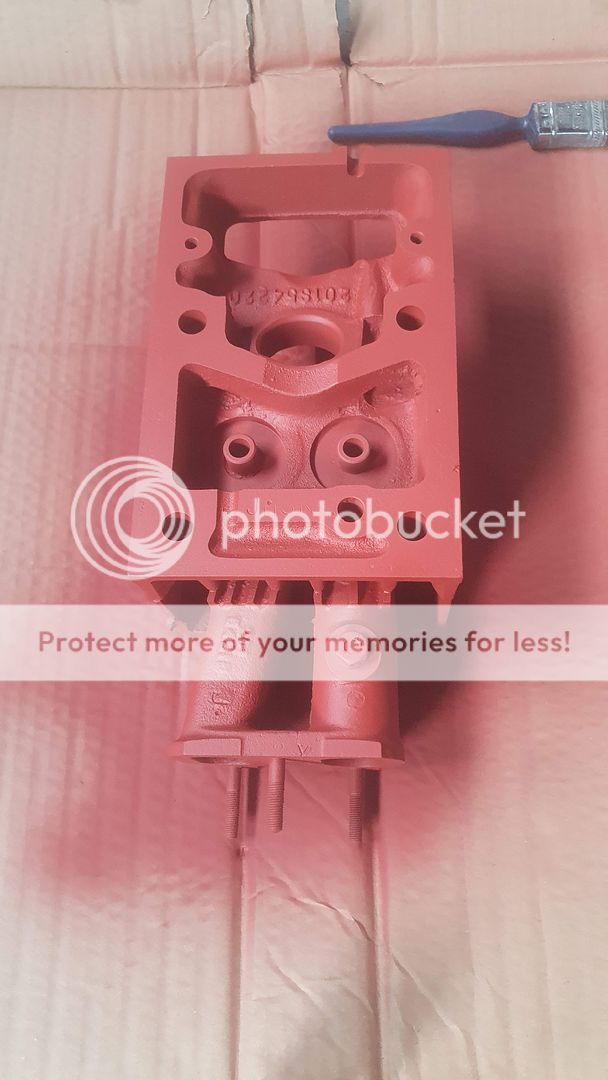

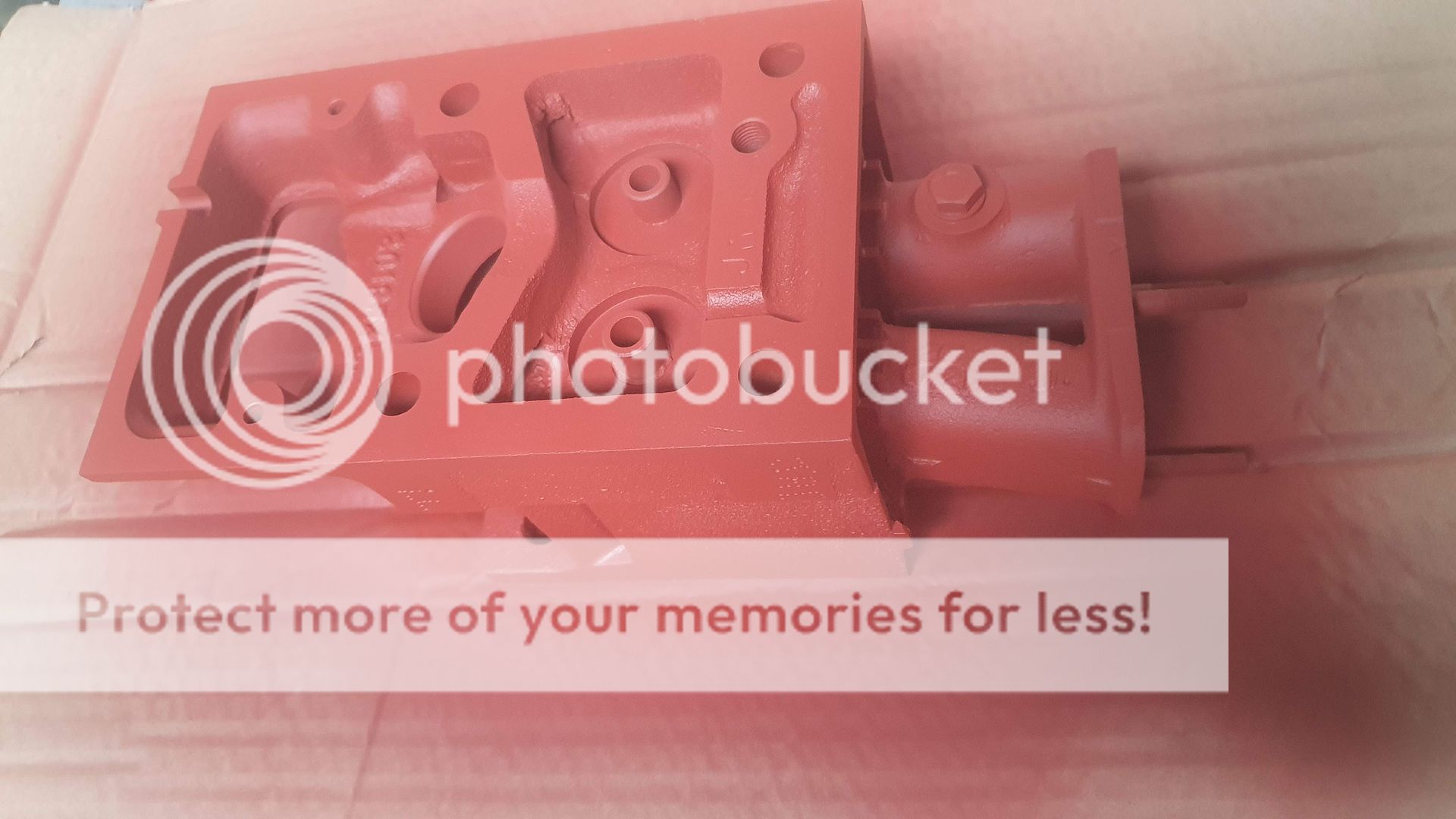

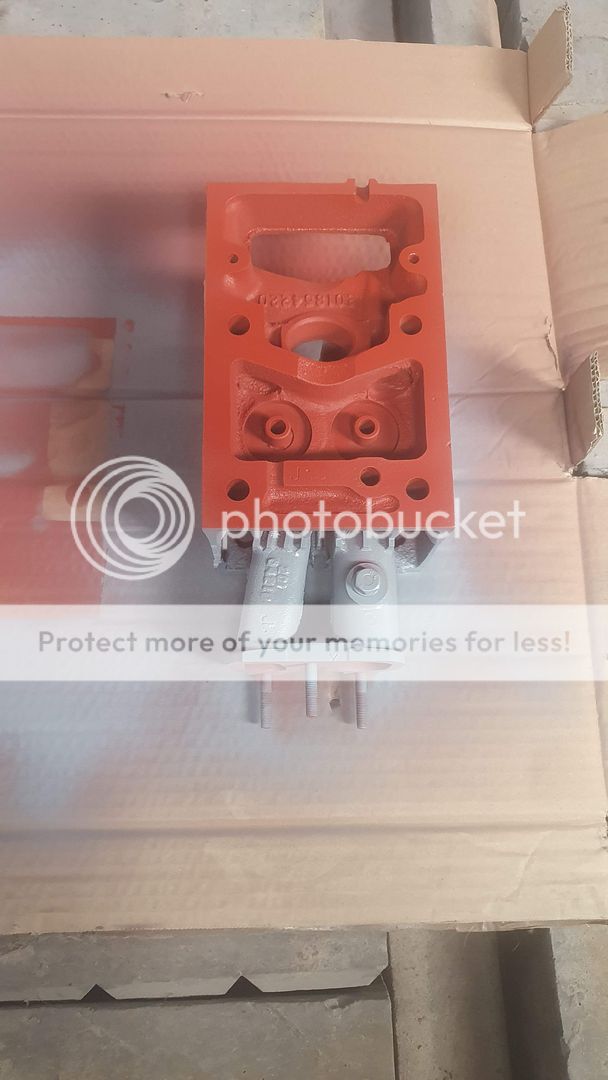

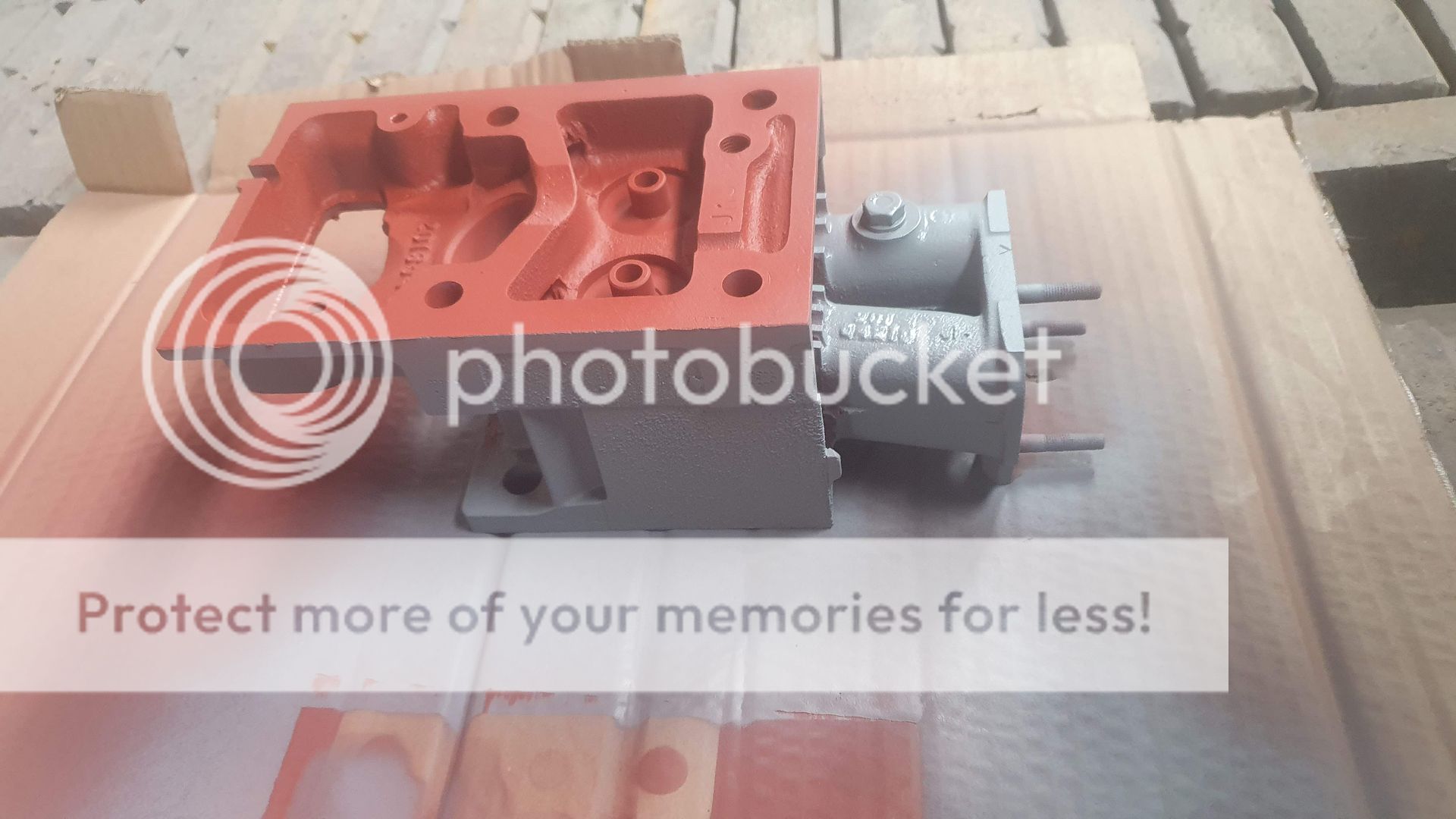

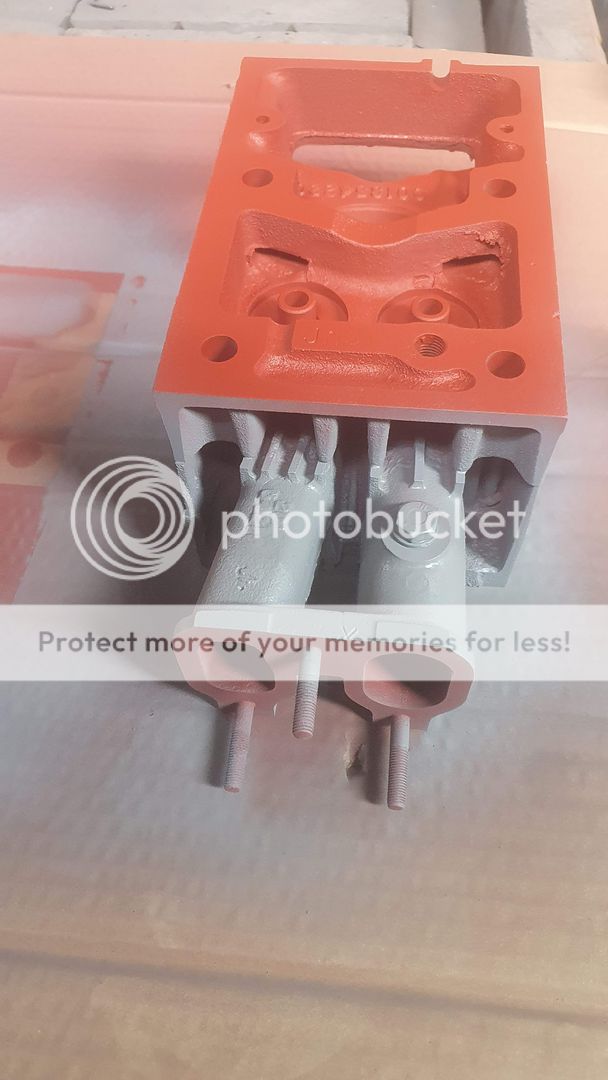

Progress has been made today with the cylinder heads for the SR2, I got a surprising phone call from the machine shop, one head was ready and the other one is being done tomorrow , I have been to pick up that one head today and have managed to start the painting process in red craft-master primer and then in the grey primer.

I am now waiting on the new valves, and valve guide materiel to turn up and then I can measure the valves and start to turn the new valve guides on my lathe.

I have also made a start on dissembling the rocker cover for one cylinder and have started shot blasting it, Then the compressor ran out of diesel so off to the garage for 40L diesel for another weeks worth of compressed air.

LW

I am now waiting on the new valves, and valve guide materiel to turn up and then I can measure the valves and start to turn the new valve guides on my lathe.

I have also made a start on dissembling the rocker cover for one cylinder and have started shot blasting it, Then the compressor ran out of diesel so off to the garage for 40L diesel for another weeks worth of compressed air.

LW