1

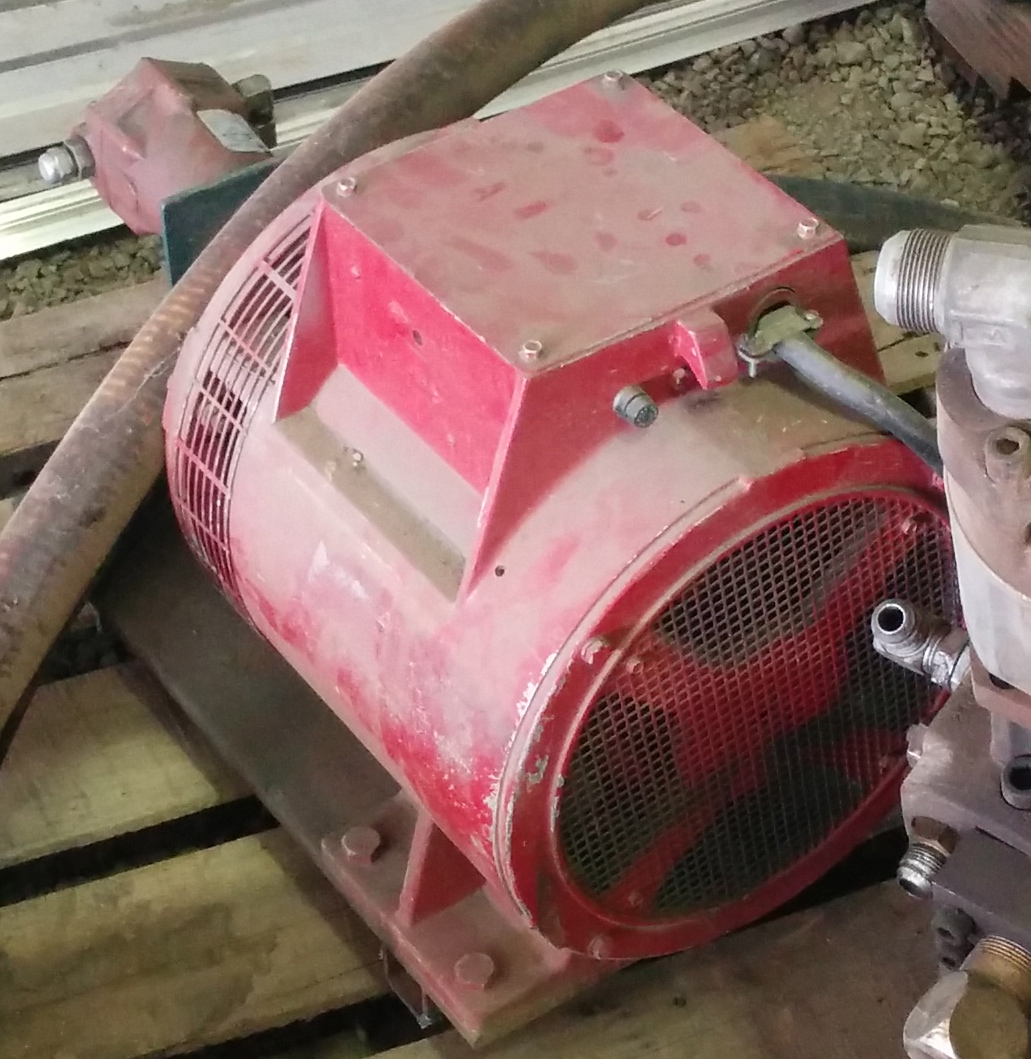

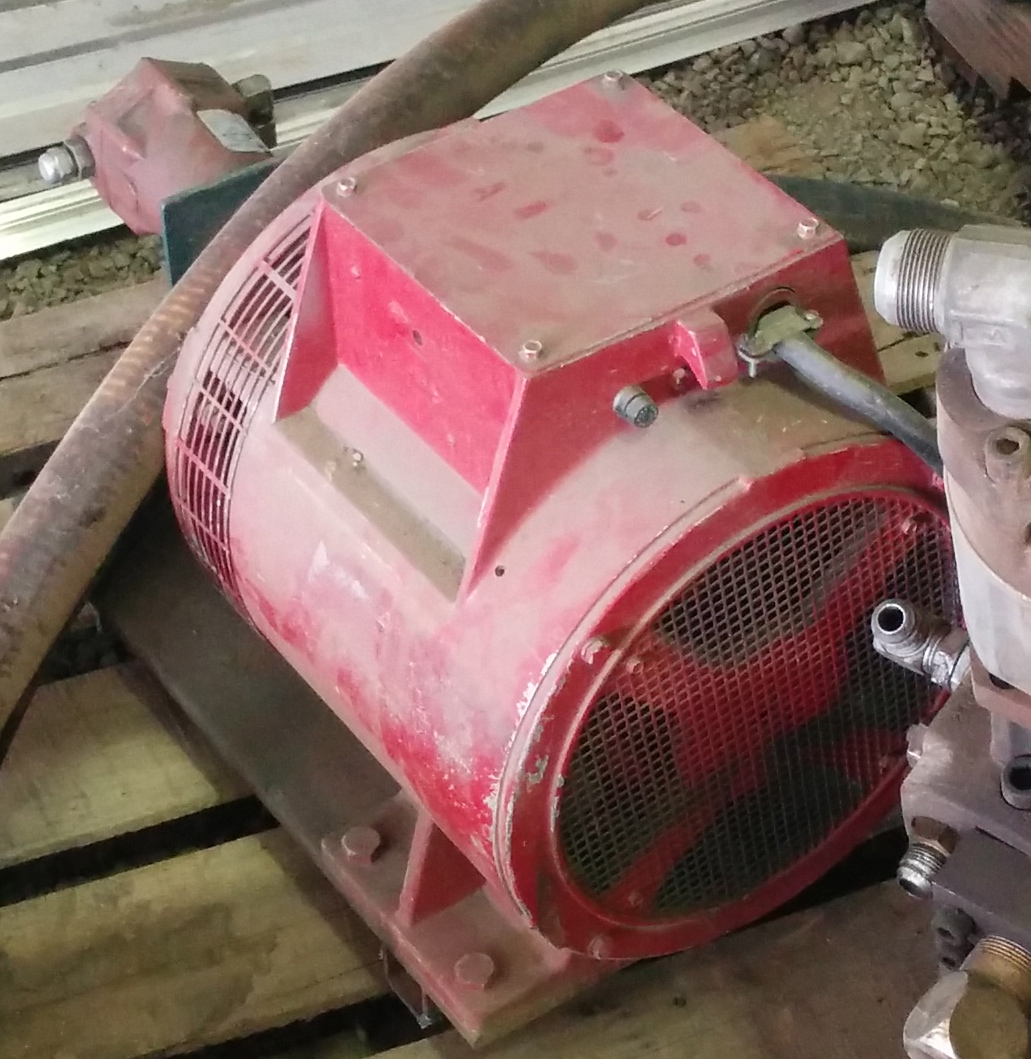

Lister Based Generators / Picked up a Lima/Marathon 3KW head...

« on: March 25, 2015, 06:39:44 AM »

...at auction. Paid $400 for it, which may be too much but I like the American-made stuff. It currently has a hydraulic motor attached to the shaft, so I'm going to put some quick-connects on it and plug it into my Bobcat takeoffs and give it a whirl and plug some space heaters into it. Eventually I'll be hooking it to one of my Lister CS 6/1 engines as a smaller "backup" generator to my main 16/2. Anyway... my questions are:

- what should I look at to ensure it's still in good shape?

- what lubrication, if any, do I need to do to it assuming it's been in storage for 10+ years?

- are there any general hints on this type of head?

JT

- what should I look at to ensure it's still in good shape?

- what lubrication, if any, do I need to do to it assuming it's been in storage for 10+ years?

- are there any general hints on this type of head?

JT

I've got an ST-10, and I'll probably end up getting a 3-5kw PMG if I can find someone who makes a quality one in the next few years, but I'm in no rush. My Lister project has suffered from lack of space, and will probably sit for the next year or so anyway, 95% complete. I've built a Changfa-195 based generator which works for my purposes in my current home, and when I start building a new house I'll get the pole barn up first, get the genset assembled, then start making power for construction. I've also got an SR-1 complete generator system, but I need to find brushes for the interesting 110v/12v generator head (early 70's vintage.)

I've got an ST-10, and I'll probably end up getting a 3-5kw PMG if I can find someone who makes a quality one in the next few years, but I'm in no rush. My Lister project has suffered from lack of space, and will probably sit for the next year or so anyway, 95% complete. I've built a Changfa-195 based generator which works for my purposes in my current home, and when I start building a new house I'll get the pole barn up first, get the genset assembled, then start making power for construction. I've also got an SR-1 complete generator system, but I need to find brushes for the interesting 110v/12v generator head (early 70's vintage.)