16

Original Lister Cs Engines / Re: Another 6/1 Restoration

« on: January 06, 2018, 08:30:44 PM »

This update is waaaaay overdue. Been on holiday and without any photographic material I dared not post anything!

Milestone met! The genset is good enough to show off and it works 100%.

There are only a few more boxes to tick to get to exactly where I want to be - for now I am however content with where I am with the project.

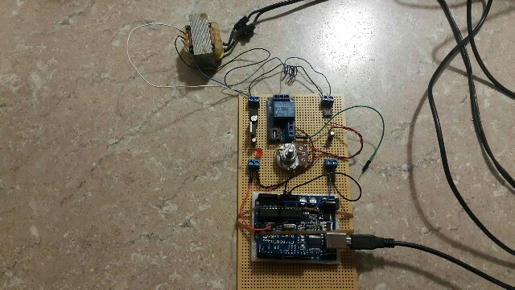

It's been an interesting journey to get the electrics sorted... With the Arduino fried the next option was to go analogue. Thanks again to BruceM for the advice and encouragement.

Circuit operation in a nutshell: Voltage coming from the alternator is scaled down to 12V and monitored by op-amp comparitors. As soon as either adjustable over- or under voltage thresholds are exceeded, the circuit energises a power relay to shed the load going to the plug outlet. There is a time dealy build in to filter out dips and spikes. When the fault condition is resolved, the circuit can be reset to connect the load again. There is a switch in the panel where the monitoring circuit can be switched off - with the power relay wired N/C the circuit can thus operate without intervention. The green LED on the panel door indicates that voltage monitoring is active.

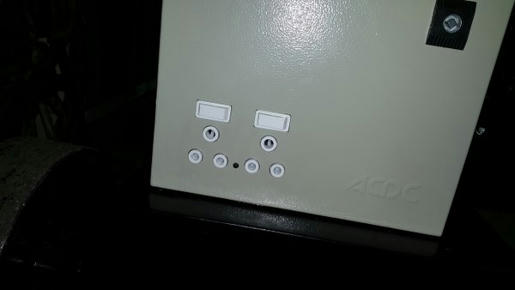

From left to right:

Plug outlet.

Non-latching pushbutton to reset trip.

Green LED - Voltage monitoring active.

Red LED - Output tripped.

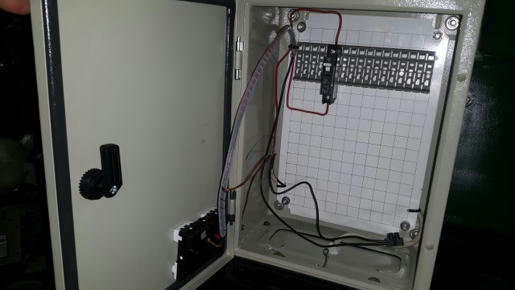

Complete circuit assembly:

From left to right:

Neutral bar.

Main circuit breaker.

Voltage monitoring circuit breaker (On/Off).

2x transformers:

One is to scale 230V to 12V for input into the comparitors.

The other is 230V to 18V to power the delay-on relay.

The brains of the circuit:

From left to right:

Power relay to disconnect load. (230V Coil).

12V relay controlled by the delay timer. These contacts operates the power relay.

Delay-on timer triggered by the voltage monitoring circuit.

A brief demonstration:

https://youtu.be/vpnZOMdcmFM

For the alternator connection box I also made a cover. Found some plate in the shed and some heavy hammerblows later I had the cover.

On the way back from our coastal holiday, we made a road trip of the 1300Km journey back home. We stopped at a couple of interesting places and avoided the main roads so we could pass through some small towns. In one of these towns called "Willowmore" we browsed through some antique shops. In one of these shops I found a Lister Diesel tank, exactly the same as the one I have, in the back of a dark shelve The tank is beyond repair, but the Lister cap is intact! Of course it had to come home with me. In no time I had it cleaned up and the piece of crap chinese-made cap was chucked sidways!

The tank is beyond repair, but the Lister cap is intact! Of course it had to come home with me. In no time I had it cleaned up and the piece of crap chinese-made cap was chucked sidways!

My to-do list to round the project off:

Guages in the panel door. (Volts, Amps, Hour meter, Frequincy)

Probably paint the panel green.

Gib head key covers.

Rocker bushes. (I'll turn these myself)

TAKE IT TO A SHOW!

Milestone met! The genset is good enough to show off and it works 100%.

There are only a few more boxes to tick to get to exactly where I want to be - for now I am however content with where I am with the project.

It's been an interesting journey to get the electrics sorted... With the Arduino fried the next option was to go analogue. Thanks again to BruceM for the advice and encouragement.

Circuit operation in a nutshell: Voltage coming from the alternator is scaled down to 12V and monitored by op-amp comparitors. As soon as either adjustable over- or under voltage thresholds are exceeded, the circuit energises a power relay to shed the load going to the plug outlet. There is a time dealy build in to filter out dips and spikes. When the fault condition is resolved, the circuit can be reset to connect the load again. There is a switch in the panel where the monitoring circuit can be switched off - with the power relay wired N/C the circuit can thus operate without intervention. The green LED on the panel door indicates that voltage monitoring is active.

From left to right:

Plug outlet.

Non-latching pushbutton to reset trip.

Green LED - Voltage monitoring active.

Red LED - Output tripped.

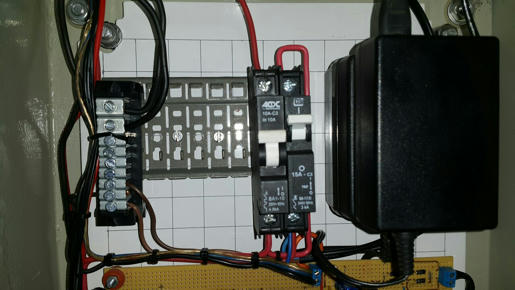

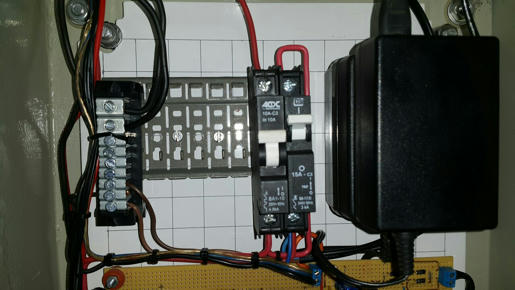

Complete circuit assembly:

From left to right:

Neutral bar.

Main circuit breaker.

Voltage monitoring circuit breaker (On/Off).

2x transformers:

One is to scale 230V to 12V for input into the comparitors.

The other is 230V to 18V to power the delay-on relay.

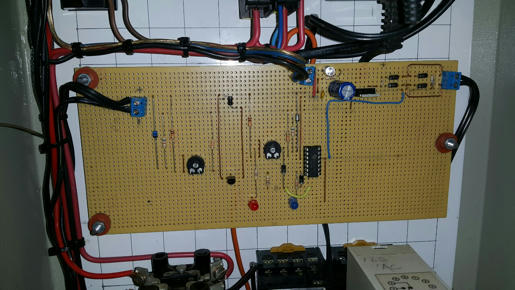

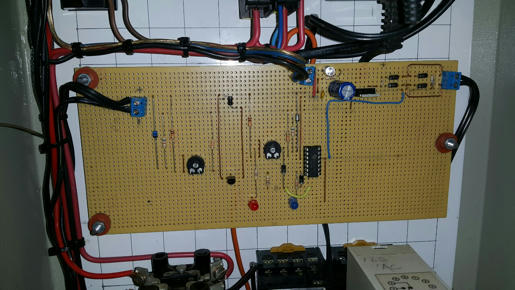

The brains of the circuit:

From left to right:

Power relay to disconnect load. (230V Coil).

12V relay controlled by the delay timer. These contacts operates the power relay.

Delay-on timer triggered by the voltage monitoring circuit.

A brief demonstration:

https://youtu.be/vpnZOMdcmFM

For the alternator connection box I also made a cover. Found some plate in the shed and some heavy hammerblows later I had the cover.

On the way back from our coastal holiday, we made a road trip of the 1300Km journey back home. We stopped at a couple of interesting places and avoided the main roads so we could pass through some small towns. In one of these towns called "Willowmore" we browsed through some antique shops. In one of these shops I found a Lister Diesel tank, exactly the same as the one I have, in the back of a dark shelve

The tank is beyond repair, but the Lister cap is intact! Of course it had to come home with me. In no time I had it cleaned up and the piece of crap chinese-made cap was chucked sidways!

The tank is beyond repair, but the Lister cap is intact! Of course it had to come home with me. In no time I had it cleaned up and the piece of crap chinese-made cap was chucked sidways!

My to-do list to round the project off:

Guages in the panel door. (Volts, Amps, Hour meter, Frequincy)

Probably paint the panel green.

Gib head key covers.

Rocker bushes. (I'll turn these myself)

TAKE IT TO A SHOW!

enjoyed the video and the write-up.

enjoyed the video and the write-up.

It looks serious... I think it's dead...

It looks serious... I think it's dead...

I'm starting to loose hope...

I'm starting to loose hope...